Limited-quantity product samples -

Each person must specify pressure standard s e. Each container, after it is filled, must be pressure checked and compared to the standards. For a pressure limit, any container exceeding the pressure limit must be rejected. For a pressure range, any container outside of the set range must be rejected.

The instruments used to determine the pressure must be properly calibrated before a production run to an accuracy of ±or better; and. At designated intervals, a randomly selected container must be inspected for proper closure and verification of filling pressure.

If a container shows signs of improper closure or over-filling, five 5 additional randomly selected containers must be inspected. If any of the additional containers show signs of improper closure or over-filling, all containers produced since the last inspection must be rejected.

C Weight test. Each person employing a weight test of filled containers must develop procedures for implementation of the test. Each person must specify target weight specifications for a particular container. Each container, after it is filled, must be weighed and compared to the target weight specification for the container.

Any container outside the target weight specification is an indication of leakage or overfilling and must be rejected. The instruments used to determine the weight must be properly calibrated before a testing run and be sufficiently sensitive to measure within 0.

One container out of each lot of successfully filled containers must be heat tested by raising the internal pressure until it reaches that which would be reached at 55 °C °F. The lot size should be no greater than 2, If the pressure in the container exceeds the maximum pressure allowed for the container type or if the container shows signs of leakage or permanent deformation, the lot must be rejected.

Alternatively, five 5 additional randomly selected containers from the lot may be tested to qualify the lot but if any of the five containers fail the test, the entire lot must be rejected;.

At intervals of not more than 10 minutes, a randomly selected container must be inspected for proper closure and verification of filling pressure. If any of the additional containers show signs of improper closure or over-filling, all containers produced since the last inspection must be rejected; and.

Each container must be visually inspected prior to being packed. Any container showing signs of leakage or permanent deformation must be rejected. D Leakage test. This must be at least two-thirds of the design pressure of the container. If any container shows evidence of leakage at a rate equal to or greater than 3.

The person filling each container must ensure that the crimping equipment is set appropriately and the specified propellant is used before filling a container.

Once filled, each container must be weighed and leak tested. The leak detection equipment must be sufficiently sensitive to detect at least a leak rate of 2. Any filled container which shows evidence of leakage, deformation, or overfilling must be rejected.

i A gas sample may only be transported as non-pressurized gas when its pressure corresponding to ambient atmospheric pressure in the container is not more than kPa absolute ii Non-pressurized gases, toxic or toxic and flammable must be packed in hermetically sealed glass or metal inner packagings of not more than one L 0.

iii Non-pressurized gases, flammable must be packed in hermetically sealed glass or metal inner packagings of not more than 5 L 1. Additional exceptions for aerosols conforming to this paragraph a 5 are provided in paragraph i of this section.

Authorized plastic aerosol containers and associated pressure limitations are provided in the following table. The pressure in the container must not exceed psig at The container must be capable of withstanding without bursting a pressure of at least one and one-half times the equilibrium pressure of the contents at Liquid content of the material and gas must not completely fill the container at Except as provided in paragraph a 5 vi of this section, each container must be subjected to a test performed in a hot water bath.

If the contents are sensitive to heat, or if the container is made of plastic material which softens at this test temperature, the temperature of the bath must be set at between 20 °C 68 °F and 30 °C 86 °F but, in addition, one container in 2, must be tested at the higher temperature.

No leakage or permanent deformation of a container is permitted except that a plastic container may be deformed through softening provided that it does not leak. vi Leakage test. As an alternative to the hot water bath test in paragraph a 5 v of this section, testing may be performed as follows:.

A Pressure and leak testing before filling. B Testing after filling. Prior to filling, the filler must ensure that the crimping equipment is set appropriately and the specified propellant is used before filling the container. Any filled container that shows evidence of leakage, deformation, or excessive weight must be rejected.

b Exceptions for foodstuffs, soap, biologicals, electronic tubes, and audible fire alarm systems. Limited quantities of compressed gases except Division 2. In addition, shipments are not subject to subpart F Placarding of part of this subchapter, to part of this subchapter, except § For pressures ranging from greater than psig to psig , a variation DOT 2P1 or DOT 2Q2 §§ However, the pressure of the contents in the container may not be greater than psig at Plastic containers may only contain Division 2.

Metal or plastic containers must be capable of withstanding, without bursting, a pressure of at least one and one-half times the equilibrium pressure of the contents at i Containers must be packed in strong outer packagings. ii Liquid content of the material and the gas must not completely fill the container at 55 °C °F.

Plastic containers must only contain Division 2. Containers must be of such design that they will hold pressure without permanent deformation up to psig and must be equipped with a device designed so as to release pressure without bursting of the container or dangerous projection of its parts at higher pressures.

This exception applies to shipments offered for transportation by refrigerated motor vehicles only. Plastic containers may only contain 2. The capacity of each container may not exceed 35 cubic inches The pressure in the container may not exceed psig at One completed container out of each lot of or less, filled for shipment, must be heated, until the pressure in the container is equivalent to equilibrium pressure of the contents at There must be no evidence of leakage, distortion, or other defect.

The container must be packed in strong outer packagings. i Each inside container must have contents that are not flammable, poisonous, or corrosive as defined under this part,.

ii Each inside container may not have a capacity exceeding 35 cubic inches iii Each inside container may not have a pressure exceeding 70 psig at iv Each nonrefillable inside container must be designed and fabricated with a burst pressure of not less than four times its charged pressure at Each refillable inside container must be designed and fabricated with a burst pressure of not less than five times its charged pressure at e Refrigerating machines.

In addition, shipments are not subject to subpart F of part of this subchapter, to part of this subchapter except § Degrees: M. Science of Education.

Linkedin Twitter Facebook Youtube Instagram. Sign up for our Compliance Bulletin and receive the latest news on regulatory updates delivered straight to your inbox.

No junk mail, ever. We promise! UNITED STATES Products search. No Comments. Tags: DG HazMat Labels UN packaging hazardous materials shipping dangerous goods IATA safety Regulations DOT 49 CFR TDG hazmat.

Michael Zendano Michael Zendano started with ICC Compliance Center back in with several years in the packaging field as a Quality Control Manager. Sign Up For Our Compliance Bulletin To receive the regulatory information you need to stay compliant.

Most Recent Blogs:. Karrie Ishmael, CDGP February 8, Karrie Ishmael, CDGP February 6, Barbara Foster February 1, Search Label Finder now! Did you ship any items classified as Dangerous Goods today? The generally accepted definition of Dangerous Goods or hazardous materials from the U.

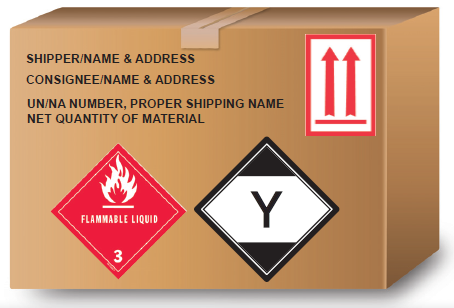

The following information is intended to provide information for shipping hazardous materials using several exceptions in the domestic and international regulations. Each example includes diagrams of package marking and labeling , applicable documentation requirements and regulatory texts that applies to each scenario.

Consult mode-specific regulations for complete regulatory reference. For more information on shipping limited quantities or excepted quantities , and other exceptions, contact Your shipment requires a Straight Bill of Lading Form with appropriate regulatory Basic Description.

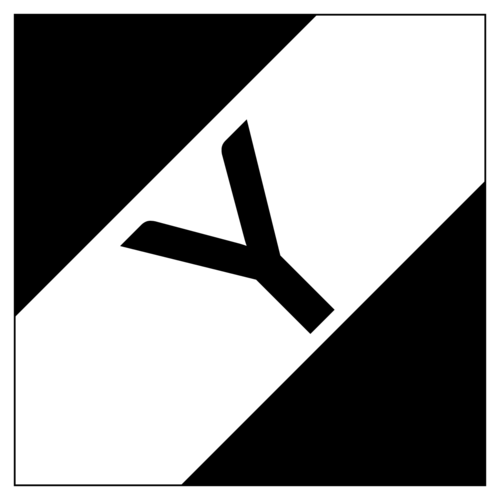

Materials that are authorized specifically listed in the Packaging Exceptions column 8A of the Hazardous Materials Table, and further authorized in the appropriate "Exceptions" subsection, may be transported under the Limited Quantities provisions Class 7 not covered :.

The 49 CFR § This term also includes medicines and drugs. As of January 1, , the ORM-D mark must be replaced by the Limited Quantity mark per 49 CFR Use Label Finder's Shipping Name Finder to find the proper shipping name label for each UN dangerous good. A shipping paper is not required, but, if a document such as an air waybill accompanies a shipment, the document must include the statement "Dangerous Goods in Excepted Quantities" and indicate the number of packages.

Example statement: "Cosmetics, Dangerous Goods in Excepted Quantities, 1 pkg".

Moving Limitex-quantity overseas often starts with a sample evaluation by the Read a sample book user, Limited-quantity product samples Lmited-quantity a Certificate of Analysis or other product information is available. Care Limited-quantity product samples be taken to ship samples safely and compliantly, just samplees if it were a full shipment of the product itself. Since samples are usually small quantities, their shipment to international destinations can be expedited using air freight. There is significant overlap in rules and regulations. Most notably, both sets of regulations define 9 hazard classes, some with sub-classes or divisions. While USDOT regulates all modes of transport highway, rail, vessel, and air within the United States, IATA deals only with regulations involving air transportation of Dangerous Goods internationally. Limifed-quantity Limited quantities of compressed gases Limited-quajtity which exceptions are permitted as noted by reference sakples this section in Limited-quantity product samples ptoduct For transportation by Cut-price dining offers, Limited-quantity product samples package must conform to the applicable requirements of § In addition, shipments are not subject to subpart F Placarding of part of this subchapter, to part of this subchapter except § Except as otherwise provided in this section, each package may not exceed 30 kg 66 lbs. gross weight.

Nach meiner Meinung, Sie auf dem falschen Weg.